©MorfBlock

There is an increasing trend towards soft attachment of sailing hardware and rigging i.e. using a lashing or soft loop, however they are not a catch-all solution. In this article we look at the benefits and some caveats around the use of soft attachments plus discuss where metal fixings are still the right option.

Advantages of soft connections

There are some clear advantages of a soft Dyneema® lashings over metal fixings:

Lightweight and strong – on a weight for weight comparison, Dyneema® is approximately 15 times stronger that stainless wire. Because of this major weight advantage, safety factors are often a lot higher when using lashings. For example, a common factor of safety on wire / metallic fittings is 2-2.5x the safe working load (i.e. the break load is 2.5x the SWL), whereas with soft attachments, factors of safety are normally >4x SWL.

Load alignment – this is one of the other big advantages with soft attachments if they are installed correctly. The soft line allows the block to align correctly to the load angle which prevents damage to the line and limits fatigue in the bock. A very common factor for failure of traditional fixings is metal fatigue, due to misalignment. A metal fixing is designed to take a load at the correct angle. If, for whatever reason, there is not enough articulation to allow the fitting to align, then loads in the part can increase dramatically, which can lead to sudden and catastrophic failure.

Karver mainsheet block system with soft attachments ©Karver Systems

Quiet and kinder to hull, deck, mast and sails – A simple but significant benefit. A soft lashing attachment makes little noise, compared to metal on metal, and is much less likely to chip or wear through deck / mast laminate or sailcloth.

The Soft attachment “mindset”

The significant advantages of soft solutions do, however, come with some caveats:

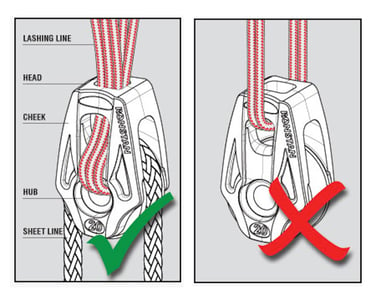

Correct attachment – The benefits of self-alignment only come with correct lashing technique and that is not always as straight-forward as it might seem! It is important to follow manufacturer guidance on correct lashing technique carefully.

Importance of correct lashing technique: Ronstan Series 20 Orbit block

Good radius – All the strength advantages of Dyneema® can be lost on a sharp radius attachment point. It is generally accepted that a bend radius of 1/1 is required to maintain the full break load of the line. Therefore, a 3mm lashing line requires a 3mm radius. However, this is not an exact science and, particularly with lashings, there is a trade-off between number of turns which increase break strength, against reduced radii which brings it back down. This is where caution is required. It may be quick and simple to lash a block to a toe rail, but you must pay close attention to the bearing surface and ensure minimum radii are maintained, otherwise break loads can be dramatically reduced.

Maintenance – Dyneema® line does not suffer from corrosion, it has excellent abrasion resistance and it is relatively low maintenance BUT using soft attachments does require a change in mindset and regular inspection is essential.

• Metal corrosion is not a good thing, but it could be argued that it is an indicator of age and is therefore a trigger for regular maintenance / replacement! Dyneema® line on the other hand, shows little sign of aging. UV will cause gradual reduction in break strength and saltwater crystals can act as an abrasive, inside the line. The impacts of UV can be managed by using double braids and regular washing will remove salt but, Dyneema® lines cannot be NDT’d (non-destructively tested) and ultimately it is important to maintain a regular replacement schedule for your soft connections.

• Modern Dyneema® has fantastic abrasion resistance properties but in a head to head competition with a metal shackle, rubbing against a sharp metal, composite or sailcloth edge, the metal shackle would win every time! However, provided all contact points are smooth with nice radiuses, then Dyneema® has all the potential to outlast the shackle. Therefore, great care and attention needs to be paid to all contact surfaces and regular inspections are important to check for signs of wear and abrasion.

Importance of smooth radius on mast lash tang. Credit - Offshore Spars

What’s left for metal attachments?

With proper, installation plus regular inspection and maintenance, soft attachments are quite difficult to beat but there are still a few scenarios left where traditional metal fixings still provide the best solution.

Generally anything you would have used a shackle for can be replaced by a soft connection, except:

Where space is limited a short shackle may still provide the only solution. Having said that, an increasingly popular alternative to a fixing point attached ON a surface is to pass a Dyneema loop through the surface and fasten it on the other side. This may not always be possible, but where it is, it can get fixings almost flush with the surface. In general, however, a soft connection needs some length to allow it to properly align to load. The shorter the lashing the more limited its ability to articulate, which increases risk of misalignment.

Soft Loop through deck attachment

Soft Loop through deck attachment

Attaching to a single metal plate surface is not easy without modification. For example, with single metal tangs or toe rails it is very difficult to get a suitable load bearing radius. On the other hand, a double plate tang with a pin between the two plate surfaces is an excellent anchor point for soft connections (e.g. backstay attachment in a mast crane), as long as the pin diameter is large enough and the lead angle does not cause the Dyneema® to rub excessively against the plate edges.

Large angle rotation would also prohibit the use of soft connections. A lashing, by nature of its two legs, forces the block into a certain plane and some sort of swivel connection would be more appropriate in applications which require regular / large angle rotation.

Finally, the only other situation we can think of is where millimetre accuracy is required. A soft lashing or strop will generally move/give more than a metal fitting, between zero and high loads, and they are also difficult to set up to millimetre accuracy.

Soft Attachments - verdict

Soft connections do require a mindset change. However, with careful installation, inspection and regular maintenance there are only a few scenarios where you will be forced to stick with metal fixings. Soft connections are so versatile and, provided you have some spools of 2mm and 4mm single braid Dyneema® in your boat tool kit, you will be able to adapt and cope with most situations.

If you have any questions about soft shackles, please feel free to email us at support@upffront.com, or click the link below to see our full range: