Image Credits: Facnor

Facnor is a specialist in designing and manufacturing furling systems, and therefore it should come as no surprise that they have a retrofit bowsprit solution.

Facnor’s range of bowsprits is made by their sister company, Sparcraft (also part of the Wichard Group), who design and manufacture masts, booms and rigging systems in France.

In this blog we will look at the key features and benefits of the Facnor bowsprit

What is the Facnor Bowsprit?

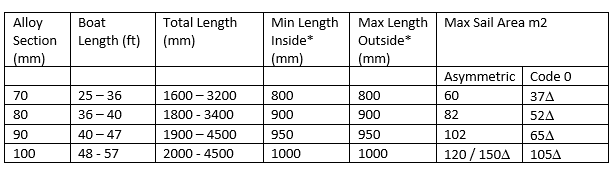

Most new-build performance cruising sailboats will have a permanent bowsprit, but a lot of older boats are without. With an increasing use of Code Zero’s and asymmetric spinnakers, the Facnor removable bowsprits offer a retrofit option for sailing boats from 25-57 feet to allow them to modernise their downwind sail inventory.

The Facnor bowsprit is a retractable, “on-deck” setup which (given the right foredeck configuration – see below), can be the simplest, most cost-effective retrofit solution and can generally be installed without the need to involve the boatyard.

How does it work?

It is a straight section alloy tube. It is retained in an articulating collar at the bow and the tube can slide forwards and backwards through this collar. When the tube is retracted, the back of the tube is placed on a “parking” fitting so that the front of the sprit is sitting at the bow in the collar. This makes it very convenient to attach/remove the furling unit to/from the front of the sprit. The tube can also easily be removed from the collar and stored along the guardrail when not in use, which leaves the foredeck completely free.

When you want to use the furling gear, the quick release fitting at the aft end of the tube is released from the parking fitting and pushed forward to a “working fitting”. The Forward deck fitting (supporting the collar) and the aft working fitting must take all the forces applied to the bowsprit, by the loaded sail, and therefore must be placed in a structurally sound area of the deck. This is generally not a problem at the bow but it is a consideration for suitable placement of the aft fitting.

The Range

See below the data for the Facnor Bowsprit range.

*The Standard lengths for the 70, 80, 90 and 100mm sections are 1600, 1800, 1900 and 2000mm respectively. You can see from the Min inside length and Max outside lengths, that the sprits are designed with the collar placed centrally along the tube. The total length of the tube can be longer BUT the forward projected length is always the same. The reason for longer tube lengths is simply to allow flexibility in the placement of the aft working fitting. The most common problem with placement of this fitting is anchor locker hatches and the aft fitting needs to be mounted behind this, on solid deck. Extra length sprits are made to order and can be finished to exact length requirements.

The size guides are generally designed so that the tube diameter alone can support the sail loads. However, for code zero’s, where the luff loads are greater, it is recommended to use the Bobstay / Bridle kit (which can be purchased as an option), which is a line running from an eye on the bow (at water level) to the bottom of the outboard end of the bowsprit, which helps support the sail load. In addition, it should be noted that for multi-hulls and very heavy displacement boats it is advisable to go up one size from the recommendations above.

Suitable bow configuration?

The one main obstacle for this type of sprit is the bow configuration. By definition, there is generally not much room at “the pointy end” and it can be a problem to find a clear path for the bowsprit tube, through the bow area.

The forward deck fitting and collar need to be as far forward as possible but this will be limited by space available for the fitting and accessibility under-deck to tighten the bolts. The biggest problem, however, is usually related to anchor gear which obstructs the path of the tube through the bow area. It is sometime possible to do a custom installation over the anchor rollers (as in the image above) but this quickly escalates the complexity of the job and should be the first item on the checklist to assess the suitability for this type of bowsprit.

Summary:

- It is a simple, robust, reliable and cost-effective retrofit bowsprit system

- It is retractable which means the furling unit is easy to attach / remove and also it reduces berthing fees at the marina

- It is also easily removable when not in use

- However, space at the bow and a clear pathway past the forestay is an important consideration

- The length required is determined by identifying a suitable location for the aft working deck fitting

If you have any questions about Facnor bowsprits, please feel free to email us at support@upffront.com, or click the link below to see our full range: