Credit Tef-Gel Australia

It’s often what you don’t see that can make the biggest difference to the life of your boat and sailing systems. Tef-Gel® is a PTFE based paste with a wide range of applications all over your boat, and its uses are not limited to the marine sector, it’s an industry standard in automotive, aviation and aerospace industries!

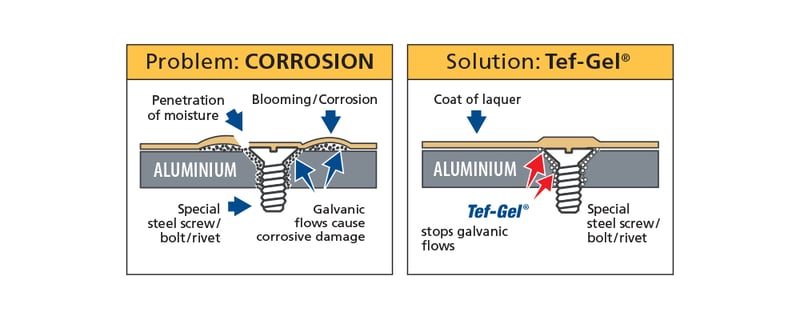

Tef-Gel’s primary use is as a galvanic corrosion inhibitor.

Galvanic Corrosion occurs when two dissimilar metals (such as aluminium and steel) are brought into contact in the presence of an electrolyte (sea water). A potential difference between the materials leads to a small flow of electrons from one to the other. The result of this electrochemical process is that the more anodic of the materials (aluminium) corrodes while the cathodic material (steel) is left unaffected.

Galvanic corrosion on an aluminium mast (credit: cruisersforum.com)

Galvanic corrosion is arguably the biggest threat to an aluminium mast and it can end up crippling your wallet as well as your rigging systems.

This type of corrosion is obvious when looking at the flat surface of the mast, however it can be even more of an issue in the places that you can’t see.

With an aluminium mast, the first visible sign is likely to be blistering around the edge of a fitting. On further inspection, the whole contact area is often found to be pitted, soft or even powdery. Eventually the metal will crumble and become unreliable.

Even if fittings have a plastic base or are otherwise insulated from the mast, most will still be secured with steel screws. Corrosion here cannot be so easily spotted. You could potentially have corrosion around the thread which will cause long term problems and, if left unchecked, lead to safety issues. That is where Tef-Gel comes in.

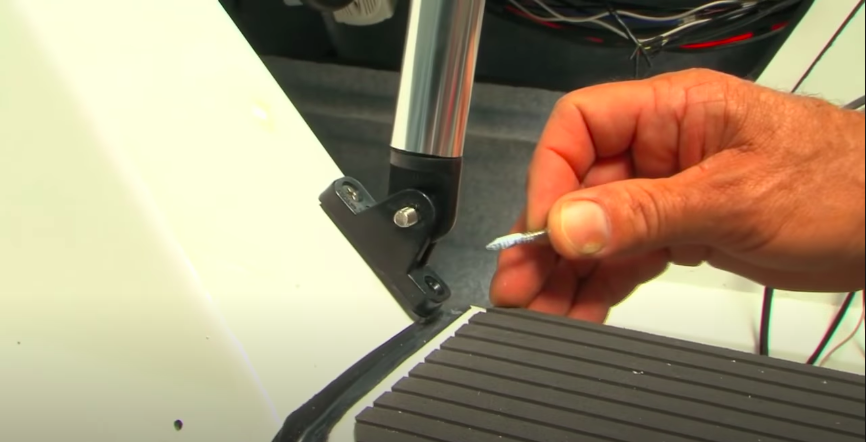

Applying a thin layer of Tef-Gel to screws and other components before installation creates an extra layer of protection, significantly increases the longevity of the metal and at the same time, blocks water ingress which is another major benefit on a sailing yacht.

Galvanic corrosion isn’t limited to metals! The same issue can even occur with carbon components when they come into contact with steel or aluminium.

As a rule of thumb, anywhere that you are connecting two dissimilar conductive materials, use Tef-Gel!

If you are servicing your rig or other components, add a layer of Tef-Gel to mounting screws, bolts and vulnerable contact surfaces before putting them back together.

This video from Tef-Gel Australia has some useful tips on how and where to apply Tef-Gel to ensure full coverage and protection, if you can excuse the elaborate virtual backdrop!

Even if the component looks fine to the eye, galvanic corrosion is a ‘silent killer’, it can start off slowly and go unnoticed for months until it develops into a very expensive problem.

Tef-Gel is completely non-toxic and not harmful to underwater eco-systems, so it can be used anywhere on your boat. The only rule is to apply it generously to ensure full coverage of the component. If you are applying it to a screw, make sure the whole thread is covered.

You really would be hard pressed to use too much Tef-Gel.

You can buy Tikal Tef-Gel® online here or if you have questions about any sailing hardware or rigging issues, then please contact us at support@upffront.com or contact us on the link below: