Armare Ropes is a 200-year-old, family owned, rope making business in Northern Italy. Upffront are pleased to launch a new range of finished torsional ropes, for code zero and asymmetric furlers, from this progressive company.

We have had an extensive range of Armare wound uni-directional, SK99, Kevlar and PBO torsional cables available to buy online for several years. However, as a rope maker, Armare quite naturally make their own torsional rope, which can be cut off-the-roll to make up cost-effective torsional cables, for boats from 20-50ft.

Despite being a relatively small manufacturer, Armare have a big reputation for performance, reliability, and service. This is most easily demonstrated by the recent announcement that they have been chosen, for the third consecutive time, as the official rope supplier to Emirates Team New Zealand, for the next America’s Cup edition.

Zero Twist Torsional Rope

Armare Ropes Zero Twist has been designed to be torsionally stiff as well as very low stretch, compared to other torsional ropes on the market. Zero Twist has a Vectran core with two layers of polyester braided cover with a special, flexible resin applied. This provides the torsional performance whilst still allowing the rope to be coiled in a relatively small diameter. Zero Twist comes in x5 primary diameters with Maximum Working Loads from 800 – 6000kg.

| Cable Dia. (mm) | Max Boat Length (ft) | Max Sail Area (m2) | Max Working Load (kg) |

| 7 | 20 | 29 | 800 |

| 9 | 25 | 37 | 1500 |

| 11 | 30 | 55 | 2500 |

| 13 | 40 | 88 | 4000 |

| 16 | 45 | 100 | 6000 |

Armare Zero Twist Specifications

At Upffront it is possible to buy cut lengths of Zero Twist to make up your own torsional cable however, we would always recommend buying a factory finished cable to ensure the best performance. Factory finished cables come with standard, reinforced stainless steel thimbles and the rope is fixed tightly onto the thimble with a Dyneema® whipping. The rope tail is stitched to the main cable and the join is then covered in a durable, heat shrink plastic cover.

How to buy online

We have tried to make it as easy as we can for you to buy these high-quality, finished torsional ropes online, but there are some important points to consider.

First, select the required diameter rope for your application and then you will be asked to choose between buying a finished cable (with thimbles) or a cut length, to allow you to finish your own cable.

Then comes the most important part – choosing the correct length. It is very important to note when buying a cut length that you need to allow an additional 300-500mm at each end for the termination of the rope around the thimble. So, if you have calculated your finished cable length of 13.75m, you actually need approx. 14.75m, to allow for the splice.

However, when buying a finished cable, we will deal with all of that for you. Finished ropes have been priced in 1 meter increments. You just need to select the next length above your required length and then tell us your exact finished length in the box provided.

Length at Load plus deductions

Length at load is an important concept and essential to understand, to ensure you get the correct length cable for your boat and/or sail. Even the stiffest ropes / cables / materials stretch under load. If we take 9mm diameter Zero Twist as an example: If we say it is 11m long at a load of 500kg, if we increase the load on the rope to 1500kg (its designed maximum working load), the rope will then be 66mm longer, at 11066mm. It is very important therefore to allow for cable stretch when a new cable is built.

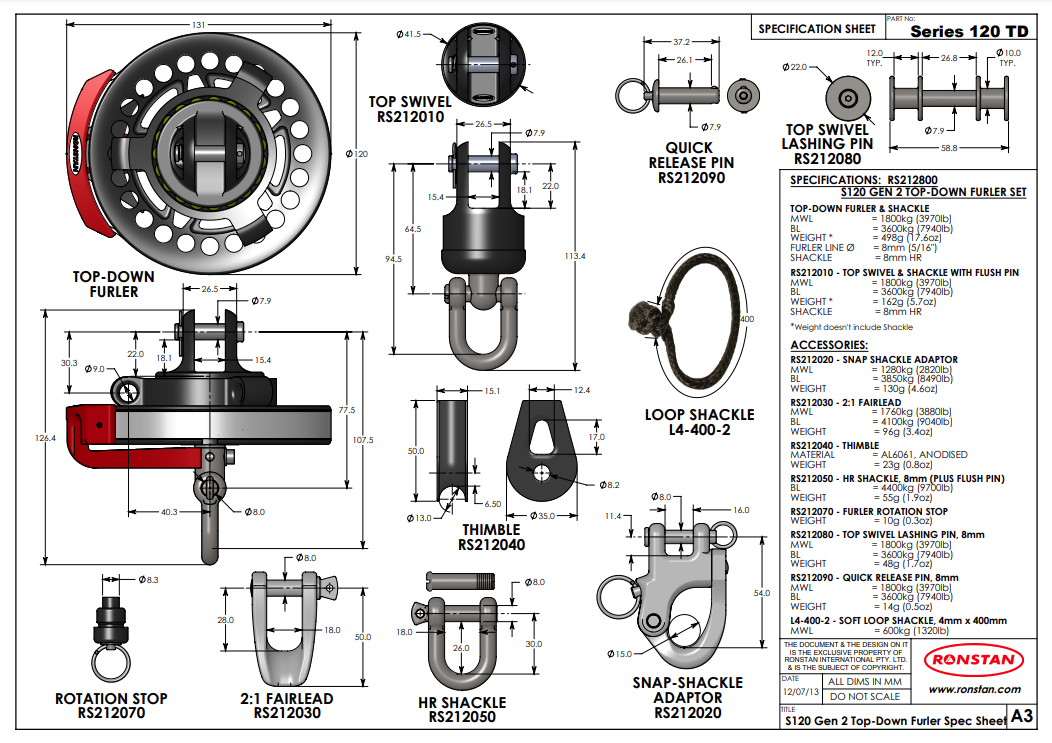

Let’s work through a detailed example to demonstrate: We have a 30ft boat and a new asymmetric spinnaker. We have measured the maximum hoist on the boat at 11300mm (for a detailed explanation of how to measure max hoist for a torsional cable read our blog here), we have bought a Ronstan Series 120 top down furler (see diagram) and want to buy a 9mm torsional cable.

From our Maximum hoist measurement, we have to make the following deductions to accommodate the furler. Starting from the top and working down:

- Top swivel shackle - 30mm

- Top swivel - 64.5mm

- Furling drum plus shackle - 107.5mm

On the assumption that the furler is being clipped to a fixed point on the end of the bowsprit (rather than a 2:1 Purchase system) then our total furler deductions are 202mm. (N.B. If you are installing a 2:1 under the drum we normally allow 200-300mm for the purchase and block under the 2:1 friction sheave on the drum.)

Measuring maximum hoist is not an exact science and you also need to allow some safety margin to account for dynamic loading on your rig. For race boats, and where we have a high degree of confidence in the maximum hoist measurement, we use a 0.5% (of total cable length) factor of safety, whereas for cruisers and/or with only a rough max hoist measurement we would use 1%. In this instance, assuming we are confident in our measurement we would apply the 0.5%, which would be an additional deduction of 56.5mm.

Therefore, 11300mm max hoist, less 202mm for furler deductions and another 56.5mm factor of safety would give us a finished cable length (from pin centre to pin centre of the cable) of 11041mm.

However, this needs to be the maximum cable length at full working load of the furling system. As we saw earlier, a 9mm Zero Twist cable can stretch 66mm from 500-1500kg, which could completely wipe out our safety margin, so it is very important to specify that the maximum length of 11041mm should be at working load. But what should that be?

To be safe – you would use the Safe Working Load (SWL) of the furling unit, which in this case is 1800kg. However, top-down furling systems do not get highly loaded (compared to code zero furlers), and it would be safe to assume a maximum of between 500-750kg. It is not an exact science but the higher the working load you specify, the shorter the cable will be built, to allow for the increased stretch at higher loads.

So, in this instance, we are going to ask for our cable to be built to 11041mm at 500kg.

Cable / Furler compatibility

This is a very important final step when buying any furling cable. You need to double check that the cable thimble will fit into the jaw of the drum/swivel and the furler pin will fit into the thimble. The thimble should be at least 0.5mm narrower than the furler jaw width. It is possible to deal with a thimble that is too narrow and/or a pin that is too small, but not the other way around! (N.B. Pin diameter is not an issue with the Armare standard stainless steel thimbles as they do not have a fixed hole)

Conclusion

Our aim at Upffront is to provide you with an extensive range of product options and also give you the tools you need to enable you to buy technical sailing products online. However, we are always here to help if you want to double check before you buy!

You can browse the Armare range of torsional ropes online, or contact us, by using the links below.